BHP’s Advanced Quality Testing Laboratory (part1)

This is especially true in the oil product producing process, the proper quality testing laboratory carries a high degree of importance. In order to manufacture the products like bitumen in different grades and as per the technical specifications ordered by customers, the raw materials need to undergo advanced laboratory testing to be classified as acceptable input for further process phases. Such laboratory tests give sufficient assurance that the application and usage of the finished product (bitumen) in the target project are safe, reliable and high-quality and also up to the required task . We believe various laboratory testing should occur before our product leave manufacturing facilities and delivered to our customers.

BHP is proud to inform its customers that its laboratory is equipped with the fully powerful and modern bitumen testing systems (PG-Performance Grade) and all main and functional components of the laboratory are made by Internationally well recognized companies in Germany & Italy. Such renovation in our quality control system has highly upgraded the quality of our product comparing to other bitumen manufacturing companies in Iran.

DSR Device :

The device determines the upper and middle PG temperature. The behavior of bitumen depends on two essential factors which are loading time and temperature. The DSR device checks the these factors accurately. Also, the device checks measure mixed shear modulus and fuzzy difference angle in the range of middle to high temperature. The test is set based on ASTM D7175 standard.

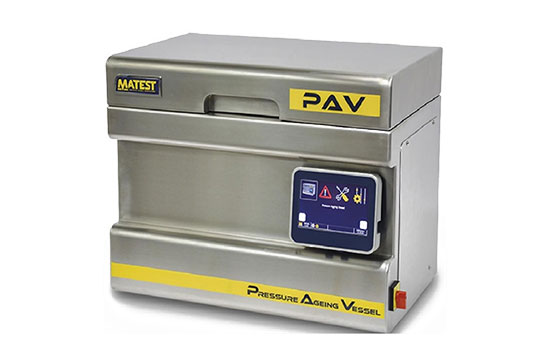

PAV (pressure Aging Vessel):

The PAV is designed to simulate in-service oxidative aging of asphalt binder by exposure to elevated temperatures in a pressurized environment.

It is clear that before any superstructure and long-term aging exposure, the bitumen is set into short-term aging conditions during asphalt mixing and fabrication. PAV test is performed for those type of samples which are aged by RTFO. The device is designed on the basis of two important factors: pressure and heating chamber and pressure control equipment and information recording. The test is set based on the ASTM D6521 standard.